NDT LEVELII Course

ndt level 2 plays an important role as it shields human life in the area of high risk. The high-risk area includes nuclear, aircraft, chemical, oil and gases, and mining industries. Ndt level 2 reduces the risk of hazard to people in an industry or plant. It is the law of every industry to maintain a safe and healthy working environment for human resources. Every employee of an industry like seasoned veterans, supervisor, plant manager of any entry-level worker not only need to understand the health and ndt level 2 risk involves in their field but also the common safety and compliance procedures. Industries like Warehouses experience a lot of forklift traffic, lifting hazards, and even slip and fall risks.

Store Management Course

Store management is a service function that basically deals with the physical storage of goods. These goods are under the custodianship of a person called storekeeper or stock controller. raw materials and unworked materials are usually referred to as stores. The place where they are kept is known as stores room. Goods stored may be either stock or stores. stock-room is the place used for housing finished products ready for shipment and are usually called stocks. The aspect of materials which is concerned with the physical storage of goods is therefore called store management. store management is the practice of controlling and managing everything within and around your store.

Pipe Fitter & Fabricator course

Pipe Fitter & Fabricator course is right now one of the most demanding course in the industry. This course is producing numerous opportunities in the current industry. Rashtriya Technical Institute (RTI) is conducting this course very effectively through the highly qualified faculty from the very competitive Industry.It is 1 Year course with 3 months crash course and total fees is RS 16500, You can even pay in two installments also. The institute has a number of spacious classrooms and practical labs equiped with all the necessary modern machinery and technical equipments for better practical experience of the students. We have a well defined and separate training methodology for all the individual courses offered

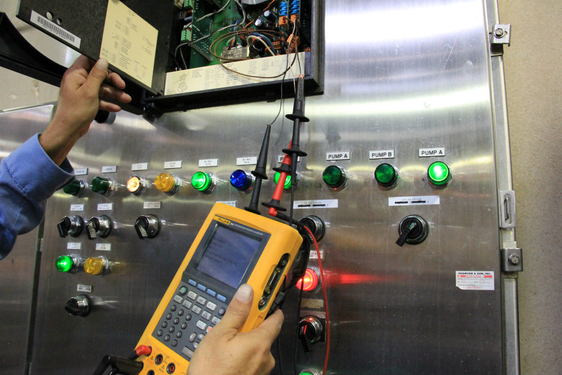

Instrument Technician Course

Instrument technician keeps track on environmental and atmospheric adjustments in buildings and industrial areas. Instrumentation technicians often work in canneries, chemical plants,food processing plants, power, food, oil, even in telecommunication industries and petroleum refineries as well as other businesses and industries that control and monitor water and air pollution. Instrument technicians main work is to maintain and repair these devices, as well as to keep a track and ensure that they comply with all the industry standards. They use a variety of devices and instruments in order to grasp these changes. These factories and industries require extremely updated and precise monitoring and measuring equipment to regulate flow and pressure rates and also to keep a track of the production.

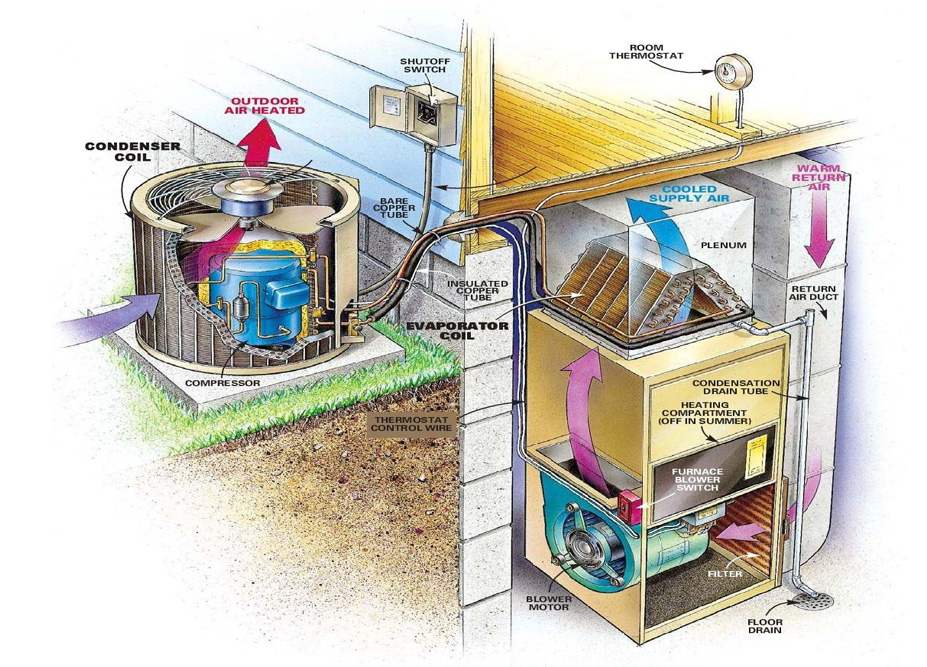

HVAC Technician Course

HVAC technician is responsible for installing, maintaining and repairing heating, ventilation, air-conditioning and refrigeration systems. A HVAC technician can work in any industrial, plant or in a factory, or in any commercial or residential building to set, install, repair and maintain the heat ventilation and air conditioning system of the regarding area. Training programs of a couple of months are provided in the Institute for HVAC technician to train an enrolling student to learn about electronics, temperature controlling system, equipment design and construction and also the installation maintenance and repairing an air conditioning system. A company needs a certified ac technician professional who has completed any training program from an authorized institution or training school.

Material Management Course

material management can be defined as “planning, directing and controlling the kind, amount, location, movement, and timing of the various flows of commodities (goods flow) used in and produced by a business enterprise — Bethel.” Material management does not only need a thorough understanding of the market but also tact, foresight, technical knowledge to plan, direct and control the whole process of materials till their absorption or disposal, if necessary. Material, in the raw state, forms the chief share of the ending product and total cost of manufacturing. This is the most significant component of the completed product and hence, should be handled with supreme concern. Material cost influence to a huge degree the rate of production and also the number of proceeds which an entrepreneur eventually earns

Land Surveyor Course

Land surveyor measures the dimensions of a particular area of the earth which involves angle, elevations and the horizontal distance of the earth surface. They also examine the artificial structures including roads or a building. A land surveyor design or draw a map or a globe on the basis of the measurement taken. They survey a particular area to identify boundaries and features of the land to determine ownership. To provide a homogeneous framework for information and geographic system, a land surveyor designs and establishes s spatial reference system.

Quality controller (QA/QC) Course

Quality control is a process through which a business ensures that the quality of a product is maintained with negligible error. in this process the quality of the product improve also. A business need to create an environment in which both management and quality control officers strive for perfection. To achieve the quality training personnel creates benchmarks for products and tests for statistically significant variations. To eliminate the employees with adequate training, inspector assigns a task to a specific employee. Therefore this process limits the room for error in the quality of the product. Testing at the various stages of production helps to identify the occurrence of a problem and also to overcome the same.

Plant AC Technician Course

Plant AC technician is responsible for installing, maintaining and repairing heating, ventilation, air-conditioning and refrigeration systems. A plant AC technician can work in any industrial or in a factory, or in any commercial or residential building to set, install, repair and maintain the heat ventilation and air conditioning system of the regarding area. Training programs of a couple of months are provided in the Institute for plant AC technician to train an enrolling student to learn about electronics, temperature controlling system, equipment design, and construction and also the installation maintenance and repairing an air conditioning system. A company needs a certified ac technician professional who has completed any training program from an authorized institution or training school.